Technology

Laser material processing is the use of laser systems in industrial processes (such as marking, cutting, texturing, welding, and engraving) enabling fast, high-quality, and environmentally friendly manufacturing.

marking

cutting

texturing

welding

engraving

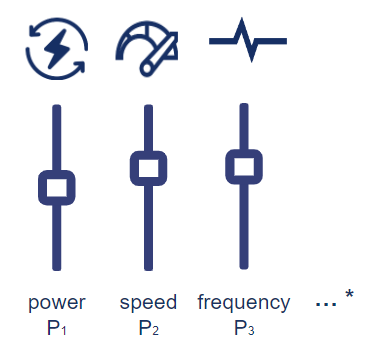

Each laser material processing application needs the right process parameters, in order to deliver the desired results. Process parameters include laser power, speed, frequency, and many more. The laser machines can only function once these parameters are tuned.

Process parameter tuning is a huge search problem

There are far too many possibilities so that a human decision maker can only hope to approach the best choices by many trial and errors.

Currently, tuning process parameters needs domain specific knowledge, significant capital investment, and consumes valuable time through trial and error, often yielding imperfect solutions due to the complexities of combinatorial problems.

Our technology approach for laser process parameter tuning

Our technical approach includes a cloud-based software enabled by following components

AI decision making and computer vision algorithmsVision-based measurement unitCustom software to control the laser systemTo tune appropriate laser system parameters, the following steps are repeated:

The AI algorithm proposes laser parameters. Parameters are passed to the laser system by our custom laser communication software.

The parameters are tried by the laser system (not an Oraclase component).

The effect is measured and evaluated by our vision-based measurement unit that uses a simple hardware and computer vision algorithm.

Learn more how our technology is used for color marking on metal surfaces